Understanding Blow Molding Technology

What is Blow Molding?

Blow molding is a manufacturing process primarily used for creating hollow plastic parts. This process involves inflating a heated plastic tube called a parison until it conforms to the shape of a mold. Once cooled, the result is a solid and lightweight product, making blow molding a popular choice for industries manufacturing containers, automotive components, and various consumer goods. The precision and efficiency of blow molding significantly impact production, ensuring high-quality output across various applications.

Types of Blow Molding Processes

There are three main types of blow molding processes: extrusion blow molding, injection blow molding, and stretch blow molding. Each of these techniques has its own unique advantages and is suitable for different types of products.

Extrusion Blow Molding

In extrusion blow molding, a parison is extruded from a plastic melt. This process is particularly efficient for producing large parts such as containers and tanks. The molten plastic is extruded into a hollow tube and clamped within a mold, where air is blown into the center to shape it. This approach is advantageous in producing thicker walls and larger items but may sacrifice some precision in thinner-walled products.

Injection Blow Molding

Injection blow molding combines the processes of injection molding and blow molding. The parison is formed by injecting molten plastic into a pre-form mold which is then transferred to a blow mold. This process is excellent for products that require a high level of precision and is commonly used for making bottles and containers with complex geometries.

Stretch Blow Molding

Stretch blow molding involves stretching the pre-form while it is being blown. This method enhances the strength of the final product, making it ideal for producing lightweight bottles and packaging materials. The stretching aligns the polymer molecules, enhancing the physical properties of the final product.

Applications and Industries Served

Blow molding is extensively used across various industries, including:

- Consumer Goods: Bottles, containers, and packaging.

- Automotive: Fuel tanks, panels, and air ducts.

- Medical: Components for medical devices.

- Construction: Hollow building materials and piping.

- Toys: Various plastic toys and games.

This wide range of applications stems from the versatility of blow molding, allowing manufacturers to produce complex shapes efficiently with reduced material waste, thus enhancing overall sustainability in the production process.

Choosing the Right Blow Molding Machine Supplier

Selecting the right blow molding machine supplier is critical for ensuring quality, reliability, and efficiency in your production line. A trustworthy Blow Molding Machine Supplier not only provides superior machinery but also supports your business with ongoing services and insights.

Key Factors to Consider

When evaluating potential suppliers, consider the following:

- Industry Experience: Suppliers with a rich history in the blow molding industry typically offer better insights and proven solutions.

- Technology and Equipment: Assess the types of blow molding machines offered, their efficiency ratings, and how they compare to competitors’ technologies.

- Customization Options: A good supplier should allow for customizing machinery to fit specific production needs, catering to both large and small productions with modular machinery options.

- After-sales Support: Reliable support for maintenance, spare parts availability, and training on machinery operation is crucial for keeping production lines running smoothly.

- Reputation and Reviews: Research customer feedback and testimonials to gauge the supplier’s reputation based on their service quality and product reliability.

Evaluating Supplier Credentials

Before making a decision, ensure that your chosen supplier possesses the following:

- Certifications: Look for ISO certifications and compliance with relevant industry standards, which indicate a commitment to quality.

- Portfolio of Clients: A robust client portfolio within your industry can illustrate the supplier’s capability.

- Innovative Solutions: Suppliers who invest in R&D tend to provide better, more innovative solutions that align with the advancing technology landscape.

Understanding Customer Support Services

Effective customer support is a vital aspect of a successful partnership. Evaluate the type of customer support the supplier offers:

- Technical Support: Availability of technicians for troubleshooting and repair.

- Training Services: Training programs for personnel on operating and maintaining the machinery.

- Response Time: Check the average response time for support queries and emergencies.

Advantages of Quality Blow Molding Machines

Investing in high-quality blow molding machines has numerous advantages, from improving production efficiency to enhancing product quality.

Improved Production Efficiency

High-quality machines often come equipped with advanced technology that enhances production speeds. Automation features reduce labor costs and increase output rates. Additionally, machines that require less downtime for maintenance enable manufacturers to achieve higher levels of operational efficiency.

Cost-Effectiveness in Manufacturing

Though the initial investment in quality blow molding machines may be higher, the long-term savings can be significant. Improved energy efficiency and reduced materials waste contribute to a lower total cost of ownership. Continuous advancements in blow molding technology lead to efficiency improvements over time, providing manufacturers with a competitive edge.

Sustainability and Material Savings

The latest blow molding machines are designed to minimize material usage while maintaining product quality. Innovations such as improved mold designs and more precise blow molding techniques enable manufacturers to achieve the same outcomes with less plastic, promoting environmentally sustainable practices. Furthermore, efficient energy consumption during the manufacturing process aligns with global efforts to reduce carbon footprints.

Case Studies: Success Stories in Blow Molding

Real-world examples illustrate how businesses have successfully leveraged blow molding technologies to enhance their operations.

Industry Leader Innovations

For instance, Uniloy, a leader in the blow molding industry, consistently integrates cutting-edge technologies in their machines, enabling their clients to realize significant production increases and enhanced product durability. By deploying advanced automation and real-time monitoring, Uniloy supports its clients in reducing costs while boosting production quality.

Customer Testimonials

Testimonials from major manufacturers highlight the importance of choosing the right blow molding machine supplier. A beverage company praised their supplier for exceptional technical support and high efficiency, noting that their investment resulted in an increased production rate of 25% while significantly reducing operational costs.

From Concept to Completion

Another well-known case involved a startup entering the consumer goods market, which relied heavily on a customized blow molding machine to produce a new eco-friendly line of products. By partnering with the right supplier, they were able to get not just machinery, but also expert advice on material selection and production processes that minimized waste and maximized sustainability.

Future Trends in Blow Molding Machinery

The blow molding industry is rapidly evolving, influenced by technological advancements and market demands.

Emerging Technologies

New technologies, such as the use of recyclable materials and bioplastics in blow molding processes, are gaining traction. These advancements not only align with the industry’s sustainability goals but also cater to the growing consumer demand for eco-friendly products.

Market Predictions

Experts predict that the global blow molding machinery market will continue to grow, driven by increasing consumer goods production, particularly in developing regions. Innovations in smart manufacturing are expected to play a significant role in enhancing manufacturing productivity and reducing operational costs.

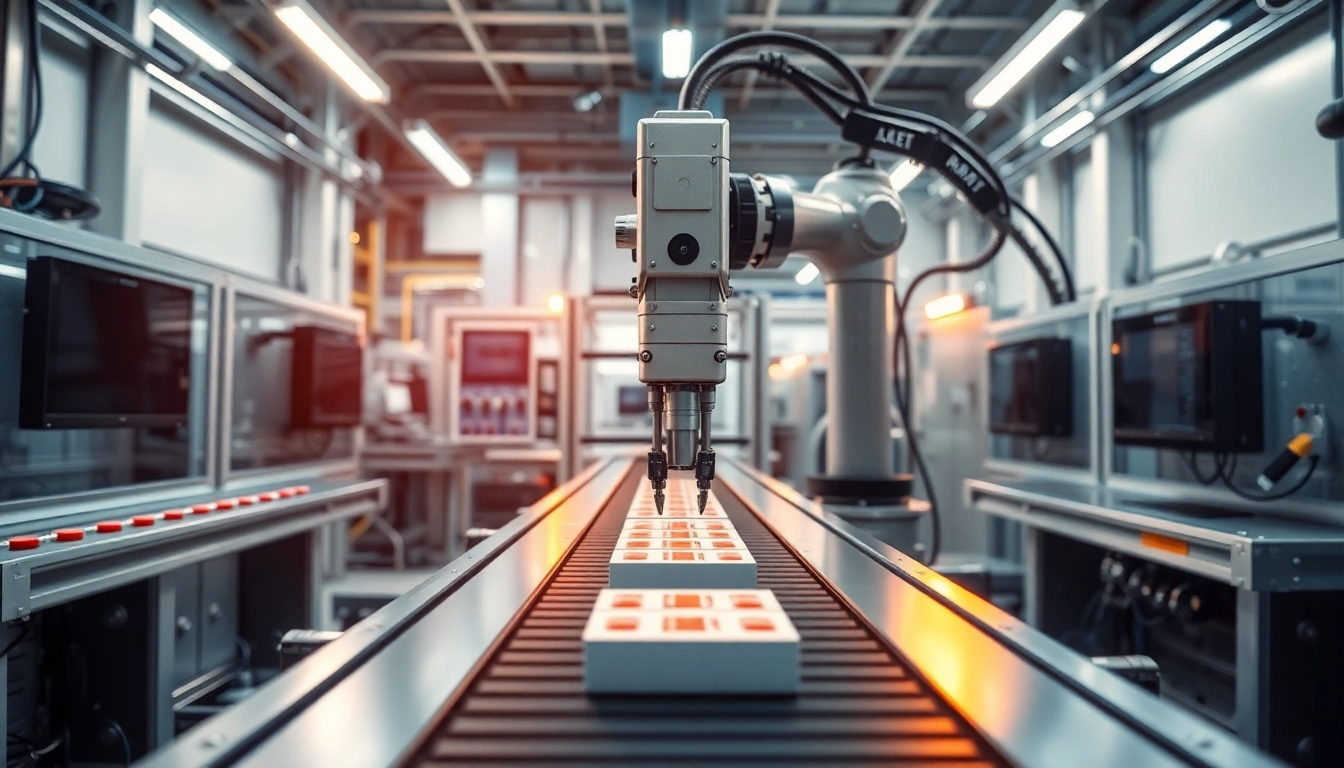

Impact of Automation on Production

The integration of automation technologies, such as robotics and artificial intelligence, into blow molding production lines is set to reshape the industry. Such implementations will streamline operations, enhance productivity, and reduce human error while enabling manufacturers to maintain high standards of quality and efficiency.