Understanding Machine Vision: Definition and Concepts

Machine vision is a transformative technology that creates an automated eye for machines, enabling them to leverage visual information for analysis and decision-making. The concept of machine vision encompasses various methods and technologies, allowing machines to interpret and react to visual input. This capability is critical in industries that prioritize efficiency, accuracy, and quality assurance.

What is Machine Vision?

At its core, machine vision refers to the ability of computers to interpret visual data. Employing sophisticated algorithms, cameras, and sensors, machine vision systems process images to automate inspection, analyze products, and even guide robotic operations. Unlike traditional imaging methods, machine vision emphasizes real-time processing and the ability to make informed decisions based on visual feedback.

The Importance of Machine Vision in Industry

Machine vision plays a pivotal role in various sectors, including manufacturing, healthcare, agriculture, and logistics. It reduces reliance on human operators for repetitive visual tasks, thus enhancing productivity and minimizing errors. Some key benefits include:

- Quality Control: Automated systems quickly identify defects or deviations from quality standards.

- Speed: Machine vision systems can inspect products much faster than manual processes.

- Data Collection: These systems create comprehensive data sets, valuable for analytics and overall process improvement.

- Cost Reduction: Minimizing human labor and mistakes leads to lower operational costs.

Key Components of Machine Vision Systems

The functionality of machine vision systems hinges on a combination of essential components:

- Cameras: High-resolution cameras capture images, playing a vital role in the accuracy of visual analysis.

- Lighting: Proper illumination enhances image quality, reducing shadows and glare that can interfere with analysis.

- Processing Unit: This hardware executes algorithms that analyze images and make decisions based on predefined criteria.

- Software Algorithms: Machine learning and AI-driven algorithms enable the system to learn from visual data, improving its performance over time.

Applications of Machine Vision Technology

Machine vision technology finds applications across a spectrum of industries. Its versatility helps enhance operations and process efficiency dramatically.

Machine Vision in Quality Control

Quality control is one of the most significant applications of machine vision. By integrating these systems into production lines, companies can ensure that products meet stringent quality standards.

For instance, in electronics manufacturing, machine vision systems can inspect circuit boards for misplaced components or soldering errors with speed and accuracy, reducing the risk of faulty products reaching the market.

Automated Inspection Processes

Automated inspection processes capitalize on machine vision by evaluating products in real-time. These assessments can detect dimensions, surface defects, or color variations efficiently. Common environments for deployment include:

- Food and Beverage Industry: Ensuring product safety and compliance with health regulations.

- Packaging: Verifying labels, expiration dates, and barcode accuracy.

- Pharmaceuticals: Monitoring dosage accuracy and packaging integrity.

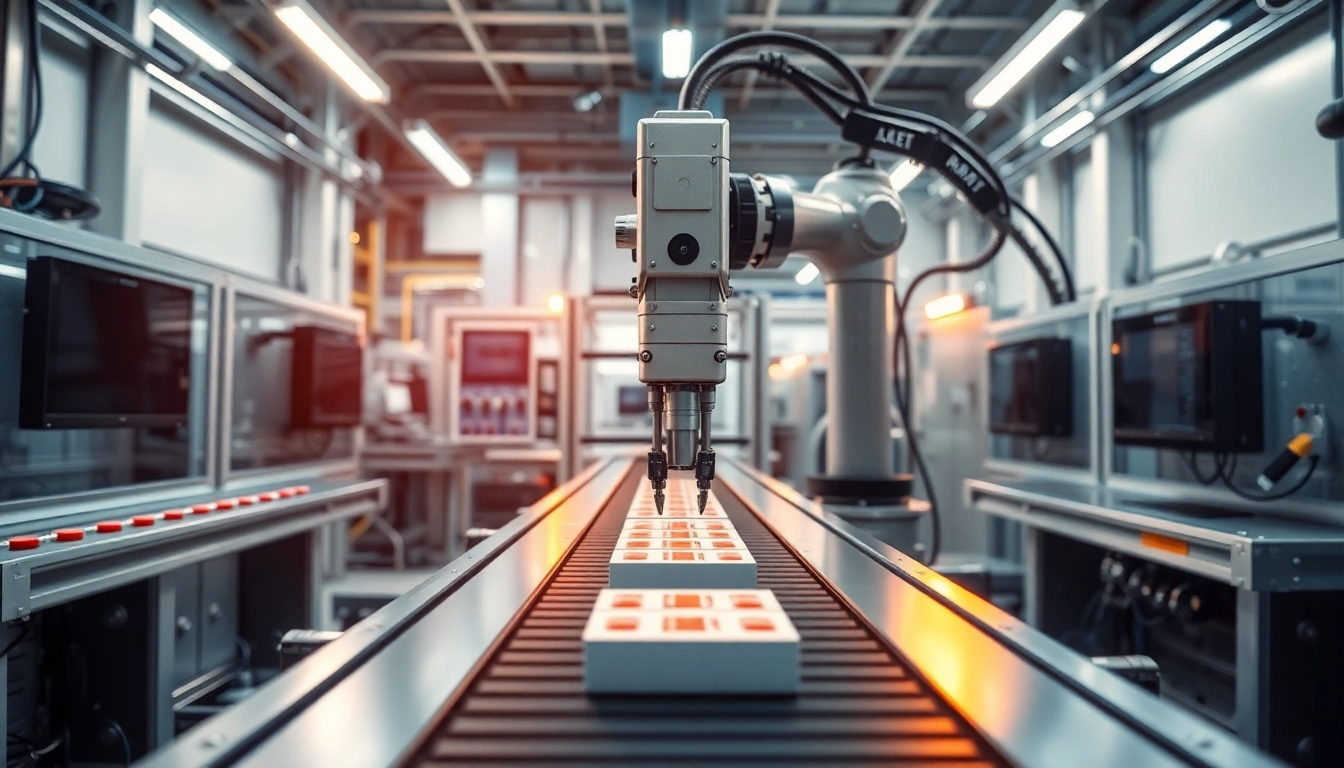

Enhancing Robotics with Machine Vision

Integration of machine vision with robotic systems enhances their operational capabilities. Robots equipped with vision systems can navigate complex environments, recognize objects for manipulation, or even collaborate with human workers safely and efficiently.

For example, in warehouse settings, autonomous robots equipped with machine vision can efficiently pick, sort, and package items by accurately identifying products and their locations.

Machine Vision vs. Computer Vision: Key Differences

It’s important to differentiate between machine vision and computer vision, as both terms are often misconstrued.

Defining Computer Vision

Computer vision refers to a field of study that focuses on enabling machines to interpret visual information similarly to humans. Unlike machine vision, which is primarily concerned with industrial applications, computer vision encompasses a broader range of contexts, including facial recognition and medical imaging.

How Machine Vision Complements AI

Machine vision serves as a vital part of artificial intelligence systems, providing the visual input needed for machine learning algorithms to function effectively. By utilizing machine vision to feed data into AI, businesses can develop smarter systems capable of making data-driven decisions, adjusting control operations, or predicting maintenance needs.

Application Differences and Use Cases

Machine vision typically focuses on specific applications in industrial settings, including:

- Defect Detection: Identifying flaws in products during the manufacturing process.

- Assembly Verification: Ensuring that products are assembled correctly and conform to specifications.

- Barcode/Label Reading: Automating data entry processes in logistics.

In contrast, computer vision is utilized in broader applications such as surveillance, autonomous driving, and augmented reality.

Implementing Machine Vision Solutions

The journey toward integrating machine vision into an operation is complex, necessitating careful planning and execution.

Choosing the Right Machine Vision System

Organizations must evaluate several factors before selecting a machine vision system:

- Application Needs: Determine what specific tasks the system must perform.

- Environment: Consider the operational environment, such as lighting conditions and space constraints.

- Integration: Ensure compatibility with existing equipment and software solutions.

- Budget: Evaluate cost versus expected return on investment.

Best Practices for Deployment

To ensure a successful implementation, follow these best practices:

- Conduct a Pilot Program: Test the system with a limited scope to gauge effectiveness before full-scale deployment.

- Train Staff: Provide comprehensive training for staff to maximize the system’s potential.

- Iterate and Optimize: Regularly analyze performance data and adjust processes as necessary.

Common Challenges and Solutions

Organizations may encounter challenges when integrating machine vision:

- Image Quality: Poor image quality can hinder performance; ensure optimal lighting and camera settings.

- Complex Environments: Address environmental factors that may interfere with vision systems through targeted adjustments and modifications.

- Integration Issues: Collaborate closely with IT and engineering teams to ensure seamless integration with existing systems.

Future Trends in Machine Vision Technology

The world of machine vision is evolving rapidly, driven by advancements in technology and increasing market demands.

Emerging Technologies in Machine Vision

New technologies are continuously emerging in the realm of machine vision, including enhanced imaging sensors, advanced lighting techniques, and new processing algorithms. These advancements promise to refine the accuracy and effectiveness of vision systems.

The Role of AI and Machine Learning

AI and machine learning will assume greater roles in machine vision. By analyzing vast amounts of data, these technologies enable systems to identify patterns, predict maintenance issues, and optimize processes, improving efficiency over time.

Market Trends and Predictions

As industries increasingly adopt automation and real-time data analytics, the machine vision market is projected to experience significant growth. Companies investing in machine vision can expect improved production efficiency, enhanced quality control, and a stronger competitive edge in their respective markets.