Understanding the Oxy Gas Welding Kit

What Is an Oxy Gas Welding Kit?

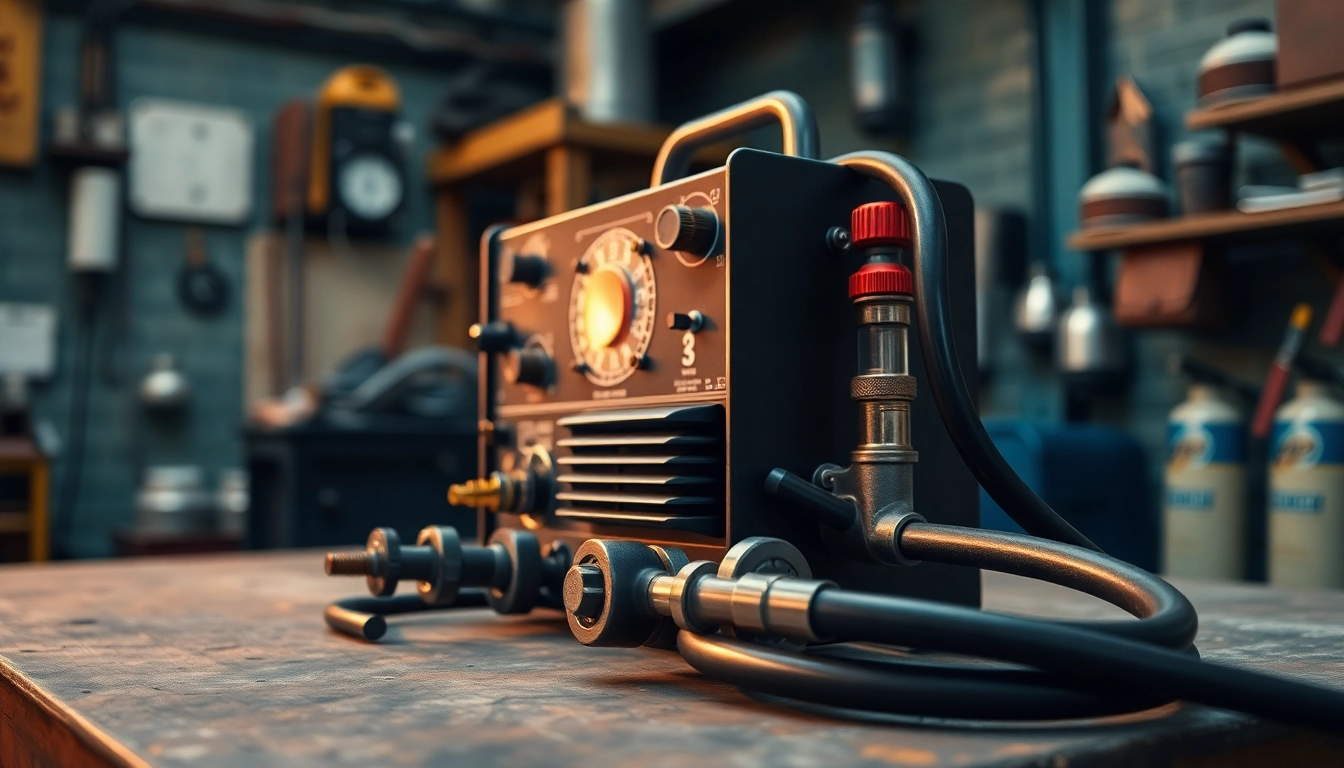

An oxy gas welding kit is a versatile and powerful tool used in various welding applications, primarily utilizing a mixture of oxygen and acetylene gases to create a high-temperature flame. This flame is capable of melting metals, allowing for effective welding, cutting, brazing, and soldering tasks. The oxy-acetylene process, developed in the late 19th century, has become a staple in many industries due to its efficiency and effectiveness in joining metals.

The basic principle behind oxy gas welding involves the chemical reaction between oxygen and acetylene, which produces a flame temperature exceeding 3,200°C (5,792°F). This high heat output makes it suitable for welding ferrous as well as non-ferrous metals, including steel, aluminum, and brass. Despite advancements in welding technology, oxy-fuel welding remains relevant due to its ease of use and accessibility for both professional and amateur welders.

Key Components of the Oxy Gas Welding Kit

An oxy gas welding kit typically consists of several essential components, each playing a crucial role in the welding process:

- Oxygen Cylinder: This tank stores oxygen at high pressure and is a necessary fuel for the welding process. Usually, it’s painted green for easy identification.

- Acetylene Cylinder: Similar to the oxygen tank, the acetylene cylinder, often colored pink or red, holds acetylene gas, which burns at high temperatures when mixed with oxygen.

- Regulators: These devices control the gas flow from the cylinders to the torch, allowing the welder to adjust the pressure and flow rates accurately. They ensure consistent supply and help maintain a steady flame throughout the welding process.

- Hoses: These flexible tubes, usually color-coded (red for acetylene and blue for oxygen), transport the gases from their respective cylinders to the torch. They should be durable and resistant to various chemicals.

- Welding Torch: The torch is a handheld tool where the gases are mixed and ignited. It is equipped with valves to control the flow of each gas and a nozzle that focuses the flame to achieve the desired welding effect.

- Welding Goggles and Protective Gear: Safety is paramount when welding. Proper eye protection, gloves, and flame-resistant clothing are essential to prevent injuries from sparks, heat, and harmful radiation.

How Oxy Gas Welding Works

The oxy gas welding process starts with the welder adjusting the regulators to control the pressure of the gases flowing from the cylinders. The user then combines the oxygen and acetylene in the welding torch and ignites the mixture with a spark lighter. The resulting flame can be adjusted to create different types of flame characteristics—neutral, oxidizing, or carburizing—depending on the specific welding needs.

In neutral flame, both gases are perfectly balanced, producing a clean, bright white flame, which is ideal for welding most metals. An oxidizing flame, characterized by a shorter and sharper cone, is suitable for cutting and welding brass and other materials. On the other hand, a carburizing flame is richer in acetylene and is used when working with iron alloys, offering better absorption of heat.

Choosing the Right Oxy Gas Welding Kit

Factors to Consider When Buying a Kit

When selecting an oxy gas welding kit, several factors should influence your decision to ensure you choose one that meets your specific needs:

- Usage Purpose: Assess whether you need the kit for light-duty tasks such as hobby projects or for heavy-duty industrial applications. This will determine the size and capabilities of the kit.

- Component Quality: Invest in a kit with high-quality components that comply with safety standards. Inspect for certifications or ratings that validate the manufacturing standards.

- Regulator Features: Look for regulators that are easy to use with precise pressure adjustment features. Gauge readability is essential for maintaining safety during welding operations.

- Portability: If you plan on working in different locations, consider a lightweight and portable kit. Cylinder size plays a significant role in the overall mobility of the welding setup.

- Budget: Determine your budget beforehand. While it’s tempting to opt for cheaper options, investing in a quality kit can save you money on repairs and replacements in the long run.

- Brand Reputation: Research different brands and read user reviews to gauge the reliability and performance of the kit you’re considering.

Comparing Different Oxy Gas Welding Brands

The market for oxy gas welding kits features several reputable brands, each offering unique products with varying features. Some of the most respected brands include:

- Victor: Renowned for durability and performance, Victor’s kits are extensively used in construction and fabrication industries. Their torch designs provide precision and excellent flame control.

- Harris: Known for affordability and reliability, Harris kits are popular among hobbyists. They offer excellent functionality for light-duty applications.

- Lincoln Electric: A significant player in the welding industry, Lincoln Electric offers high-quality kits suited for heavy-duty applications.

- ESAB: ESAB is recognized for innovative designs that enhance the welding experience. Their kits often come with advanced safety features.

Top Oxy Gas Welding Kit Recommendations

Here are some highly recommended oxy gas welding kits suitable for various applications:

- UNIMIG Oxygen-Acetylene Gas Kit: Ideal for general-purpose welding and cutting tasks, this kit is compact, including all necessary components for beginners.

- Lincoln Electric Oxy-Acetylene Torch Kit: A robust kit designed for professional welders, suitable for industrial applications.

- Harris 24-B Style Oxy Acetylene Welding Kit: This versatile kit is ideal for a range of applications from light fabrication to maintenance, featuring easy-to-use components.

- ESAB Mini Oxy-Acetylene Welding Kit: Perfect for portable jobs, this lightweight kit allows easy transport while maintaining performance.

Setting Up Your Oxy Gas Welding Kit

Safety Precautions for Oxy Gas Welding

Safety is crucial in oxy gas welding due to the inherent risks involved. Here are some essential precautions:

- Workspace Preparation: Ensure your workspace is well-ventilated and free from flammable materials. A stable work surface will also help prevent accidents.

- Personal Protective Gear: Always wear appropriate PPE, including welding gloves, safety glasses, and flame-resistant clothing.

- Gas Cylinder Handling: Transport gas cylinders in an upright position and secure them to prevent tipping. Always check for leaks before use.

- Proper Torch Use: Familiarize yourself with the function of each component of your torch. Never point the torch at yourself or others.

- Cylinder Storage: Store gas cylinders according to manufacturer guidelines, away from direct sunlight and heat sources.

Step-by-Step Setup Guide

Setting up your oxy gas welding kit correctly is vital for ensuring safety and performance. Follow these steps:

- Start by checking the condition of your gas cylinders and their relevant regulators.

- Secure the cylinders in an upright position and attach them to the regulator. Ensure the connections are tight.

- Connect the hoses to the appropriate gas outlets on the regulators (blue for oxygen and red for acetylene).

- Check for leaks by applying a soapy water solution to the connections. If bubbles form, tighten the connections further.

- Adjust the regulators to set the pressures to the recommended values before igniting the torch.

- Open the torch valves slowly, ignite the tip using a flint lighter, and adjust the flame as necessary.

Common Mistakes to Avoid

Even seasoned welders can make mistakes when using an oxy gas welding kit. Here are some common pitfalls to steer clear of:

- Forgetting Safety Gear: Never underestimate the importance of protective gear. It’s essential for preventing serious injuries.

- Improper Flame Adjustment: An incorrectly adjusted flame can lead to poor quality welds or even burn-through of materials.

- Neglecting Equipment Maintenance: Regular checks and maintenance of your equipment help ensure safety and optimal performance.

- Insufficient Preparation: Failing to prepare your workspace can lead to hazardous situations. Always assess your environment before starting work.

Techniques for Effective Welding with Oxy Gas

Basic Welding Techniques Using the Oxy Gas Kit

For beginners, mastering the basic techniques of oxy gas welding is crucial. Here are essential techniques to practice:

- Stringer Beads: These consist of single rods of metal deposited along a weld line. They are ideal for beginners to develop control over the torch and the weld pool.

- Weaving Patterns: This involves moving the torch back and forth or in a circular motion to spread the weld pool for larger areas. It’s especially used for thicker materials.

- Control the Heat: Maintain a consistent distance from the work surface and control the flame to avoid overheating and warping.

- Practice with Scrap Metal: Utilize scrap pieces to hone your skills without the pressure of a final product.

Advanced Welding Techniques for Professionals

For experienced welders, advanced techniques can significantly enhance welding quality and efficiency. Some of these include:

- TIG Welding Integration: Some welders combine oxy-acetylene with TIG welding for specialty applications, allowing for precision and intricate work.

- Multi-Pass Welding: A technique utilized for thick materials, applying multiple layers of welds to ensure integrity and strength.

- Minimizing Distortion: When welding on large panels, the use of pre-heating and maintaining a steady pace can help prevent warping and distortion.

Troubleshooting Common Welding Issues

Even the most experienced welders may encounter issues during the welding process. Here’s how to troubleshoot common problems:

- Inconsistent Weld Beads: Check your gas flow rates and ensure your torch is correctly adjusted. Inconsistent travel speed can also lead to uneven beads.

- Porosity in Welds: This may occur due to trapped moisture or contamination. Ensure your materials are clean and dry and check your flame settings.

- Excessive Spatter: This can signal that the flame is too hot or that the torch is too far from the work surface. Adjust your techniques accordingly.

- Weld Pool Too Shallow: A shallow pool often results from inadequate heating. Increase heat input and travel speed to achieve the desired depth.

Maintaining Your Oxy Gas Welding Kit

Regular Maintenance Checks

To ensure longevity and performance of your oxy gas welding kit, regular maintenance is crucial. Schedule periodic checks on the following:

- Cylinders: Inspect gas cylinders for leaks, dents, or rust. Regularly check gauge functionality.

- Regulators: Ensure connections are tight and functioning correctly. Look for signs of wear or damage.

- Hoses: Check hoses for cracks or leaks and replace them immediately if any damage is found.

- Torches: Regularly clean torch tips to remove clogs that may affect gas flow. Ensure that all parts are securely fastened.

Caring for Gas Cylinders and Torch Heads

Proper care of gas cylinders and torch heads significantly impacts their effectiveness and safety. Follow these tips:

- Storage: Store cylinders upright in a cool, dry area away from direct sunlight or heat sources.

- Handling: Always handle cylinders with care to avoid dropping or rolling, which may cause damage.

- Cleaning: Regularly clean torch heads with a soft brush to remove any residue that could affect performance. Avoid abrasive materials that may cause scratches.

Extending the Lifespan of Your Welding Kit

To maximize the lifespan of your oxy gas welding kit, implement these strategies:

- Limit Exposure to Elements: Keep the kit indoors and protected from moisture, which can cause corrosion.

- Routine Inspections: Conduct regular inspections to identify wear and tear early, allowing for timely repairs.

- Proper Usage: Follow manufacturer’s guidelines for use and avoid over-stressing components during operation.

- Quality Components: When replacing parts, invest in high-quality components that meet safety and performance standards.